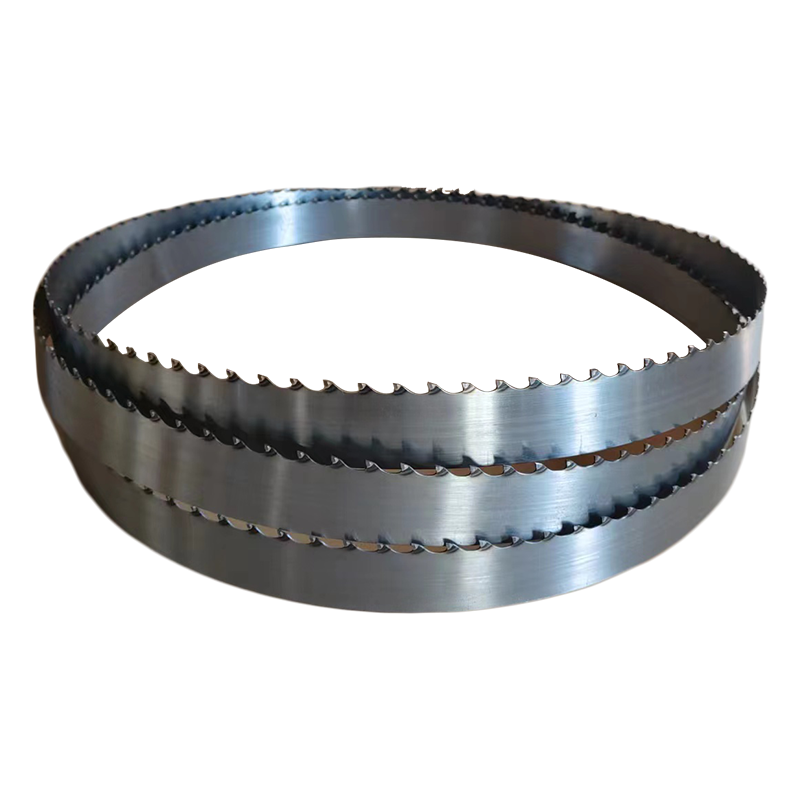

Premimum D6A 75Ni8 alloy steel carbide tipped bandsaw blades for wood

Premium D6A 75Ni8 Alloy Steel Carbide Tipped Bandsaw Blades are engineered for professional woodworkers, cabinet makers, and sawmill operators who demand exceptional cutting performance and longevity.

This premium blade combines the unique properties of a high-strength D6A alloy steel backing with the cutting-edge sharpness and wear resistance of industrial carbide tips, creating a cutting tool that outperforms conventional blades in precision, speed, and lifespan.

Designed specifically for wood, lumber, and log cutting applications, this blade is your ultimate solution for high-efficiency sawing operations.

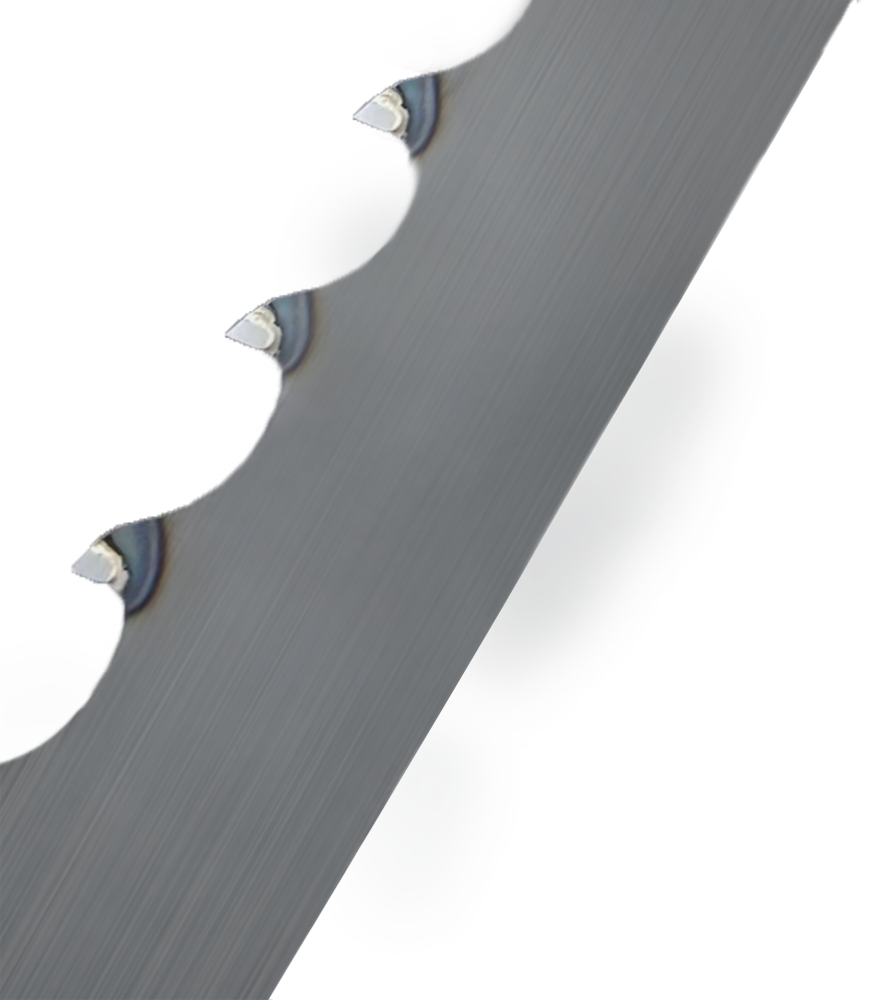

D6A High-Alloy Steel Backing: Provides superior strength, flexibility, and resistance to fatigue, ensuring the blade can withstand the tension and stress of continuous operation without stretching or snapping.

75Ni8 High-Nickel Alloy Layer: This intermediate layer contributes high toughness and resistance to corrosion, making the blade exceptionally durable under demanding conditions.

Carbide Tipped Teeth (TCT): The hardest material used for cutting edges, carbide tips stay sharper up to 100x longer than standard steel teeth, allowing for faster, cleaner, and more consistent cuts through hardwoods, abrasive materials, and composite woods.

| Material | 75Ni8, D6A |

| Thickness | 0.40mm to 1.65mm |

| Width | 4mm to 265mm |

| Tooth pitch | 10mm to 50mm |

| Tooth treatment | carbide tipped |

Why Choose Our Premium Blades?

- Extreme Longevity: The synergy of D6A/75Ni8 backing and carbide tips dramatically reduces the frequency of blade changes, maximizing your machine's uptime and lowering your cost per cut.

- Superior Cut Quality: Expect glass-smooth cuts with minimal sanding required, saving you time and material in the finishing stage.

- Enhanced Productivity: Maintain high cutting speeds and aggressive feed rates without compromising finish quality or blade integrity.

- Versatile & Reliable: Equally effective on softwoods, hardwoods, glued panels, and pressure-treated lumber, providing one-blade performance for a wide range of tasks.

Quality Assurance & Support

- Certified Manufacturing: Our production processes adhere to stringent international quality standards, including ISO9001.

- Robust Packaging: Each blade is carefully oiled to prevent rust, coiled with protective plastic on the teeth, and shipped in a sturdy carton to ensure it arrives in perfect condition.

- Expert Support: Our technical team is available to help you select the perfect blade specification for your application and provide troubleshooting advice.