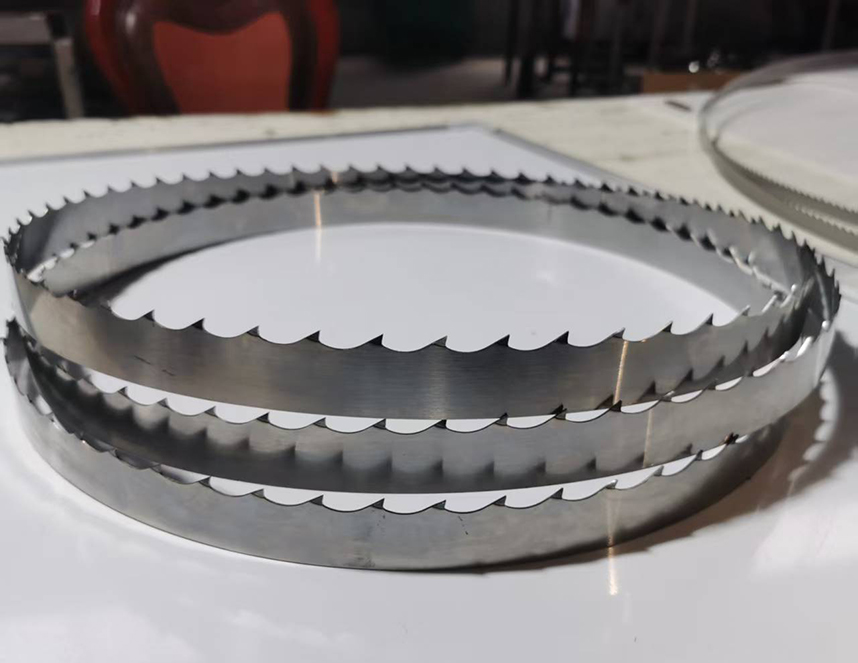

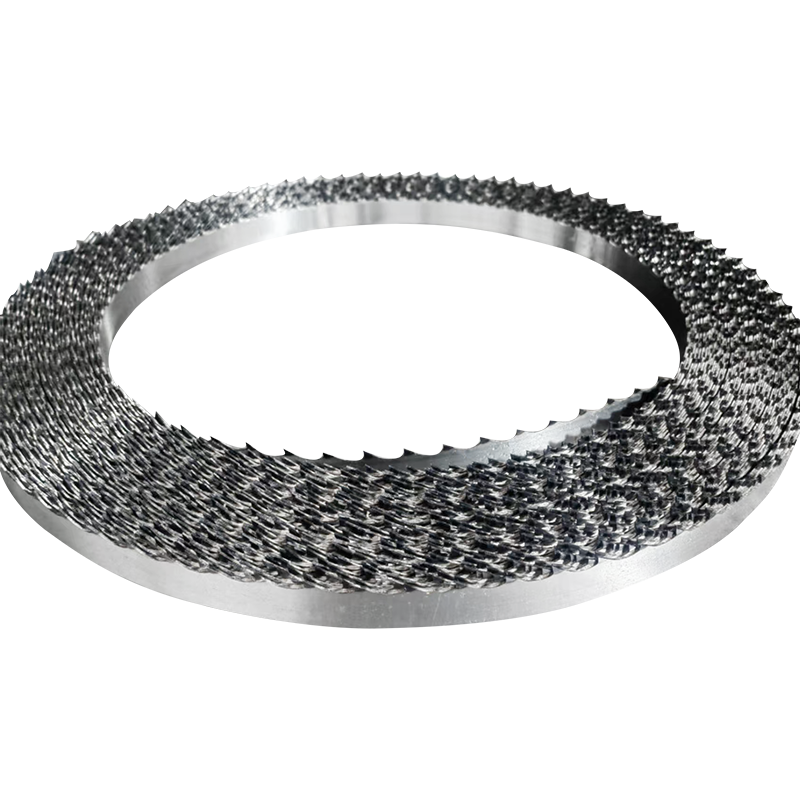

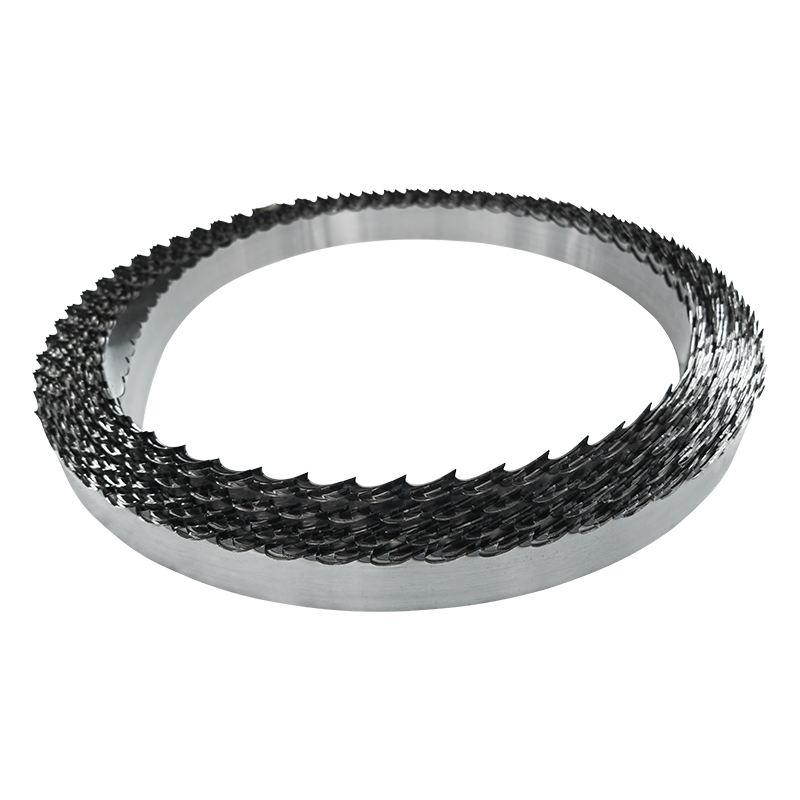

Hardened tooth tipped carbon steel sawmill bandsaw blade for wood cutting

This Hardened Tooth Tipped Carbon Steel Sawmill Bandsaw Blade is engineered for professional sawyers and mill operators who prioritize longevity, performance, and value. Unlike standard carbon steel blades, our teeth undergo a specialized hardening process, creating a cutting edge that resists wear and maintains sharpness significantly longer. Built on a tough, flexible carbon steel band, this blade delivers the perfect balance of durability and cut quality for high-volume wood cutting.

Advantages:

Extended Blade Life: Hardened teeth dramatically reduce wear, meaning fewer changes and lower cost per board foot.

Superior Cut Quality: Cuts straighter and smoother, producing higher-quality lumber with less sanding required.

Proven Compatibility: Fits most major portable and stationary sawmill brands.

Optimal Performance: The carbon steel body provides excellent flexibility and shock resistance, reducing the risk of breakage.

| Material |

CK75 SAE1075 C75S 75CR1 SK5 D6A 51CrV5

|

| Thickness |

0.042", 0.045", 1.07mm, 1.1mm, 1.15mm

|

| Width |

1- 1/4", 31.75mm, 32mm, 38.1mm, 50mm, 60mm

|

| Lenght |

in coil, 144", 158", 178" , 4031mm, 4010mm, 4670mm etc

|

| Tooth Pitch |

7/8", 3/4", 22mm, 22.5mm, 19.05mm

|

| Hook Angel |

7°: for frozen, tropical wide-cut sawmills 9°: for seasoned, hardwoods for sawmills making narrow cuts on smaller logs 10°: all-purpose for a mix of hard and softwoods on all sawmill

|

Technology & Advantages Deep Dive

1. The Hardened Tooth Tip Advantage

Each tooth undergoes a localized heat-treatment process. This creates an extremely hard, wear-resistant cutting edge while keeping the tooth body and the blade band tough and flexible. This means the blade stays sharper up to 3x longer than a non-hardened carbon steel blade when cutting abrasive woods like oak, maple, or frozen timber.

2. High-Performance Carbon Steel Body

We use a premium carbon steel alloy, carefully tensioned and stress-relieved. This provides:

Excellent Fatigue Resistance: Withstands the constant bending around mill wheels.

Reduced Breakage: More forgiving to minor mill misalignments or unexpected knots.

Faster Break-In: Gets to optimal cutting performance quicker than some harder alloys.