75Cr1 High Carbon Steel: A Brief Introduction

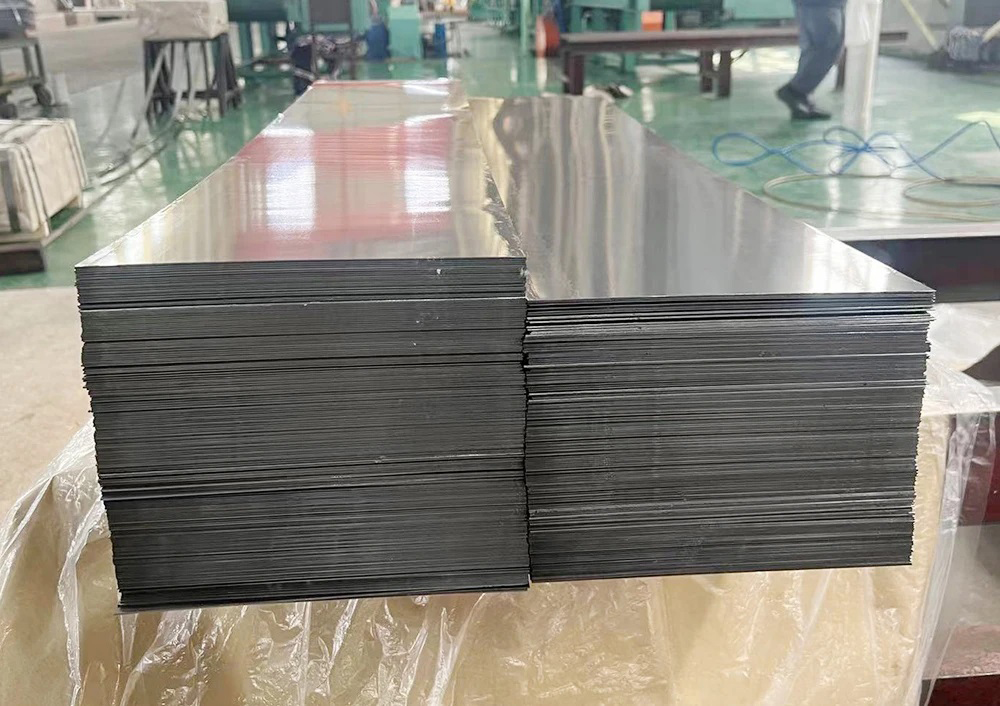

75Cr1 steel is a high-carbon chromium alloy steel known for its excellent combination of hardness, strength, and good wear resistance. This grade is primarily supplied in the form of strip coil sheet,often produced as cold rolled steel strip 75Cr1 to ensure superior dimensional accuracy, a smooth surface finish, and enhanced mechanical properties.

The key to 75Cr1's performance lies in its chemical composition. The carbon content provides the fundamental hardness, while the addition of chromium improves hardenability, allowing for a more uniform hardness profile during heat treatment. This makes it an ideal material for applications requiring a sharp, durable cutting edge that can maintain its properties under stress.

Primary Applications and Uses

The most prominent uses of 75Cr1 steel are in the manufacturing of cutting tools. It is a preferred material for high-performance bandsaw blades and circular saw blades used for cutting wood, plastics, and non-ferrous metals. Beyond saw blades, 75Cr1 is also extensively used in knives, springs, hand tools, and various wear parts. Its reliability and consistent performance make 75Cr1 steel sheet and plate a trusted choice for industrial manufacturers worldwide. For more information, welcome to visit the product link: https://www.gdgwsteel.org/product/high-quality-75Cr1-steel-strip.html

In summary, whether you are sourcing 75Cr1 steel strip for precision tooling or 75Cr1 steel plate for heavy-duty components, this versatile alloy delivers the necessary durability and cutting performance for demanding applications.